The Tiny Cedar Flea (TCF) uses the NACA 23112 airfoil which stalls at just over 12 deg Angle of Attack. Or does it?

Enter Axel Darling, a highly regarded aerodynamicist and Flying Flea enthusiast who wrote in Pou Renew #41 as follows:

The French terminology can be a little confusing – so here’s a quick glossary:

Enterplan: the positional relation of the two wings (i.e. the wing separation)

Eh: The horisontal separation of the wings

Ev: The vertical wing separation

“I found that there is a solid relationship to laminar flow at

equal entreplans. So, therefore I recommend 65/65,

70/70, 80/80 or whatever you choose, however the

greater the entreplan the better up to a point and more

specifically it relates to the vertical to keep a smooth

flow.”

Basically, Axel discovered that if the vertical and horisontal wing separations are identical, the airflow over both wings becomes laminar. So the question is – why did it take so long to discover this? In Axel’s words: “everyone has ignored [this] for decades because changes in Ev have little effect while turbulent”. Every Pou ever built has very small horisontal wing separation but much larger vertical wing separation. Some even have zero horisontal separation. There is absolutely zero chance of laminar flow on these Fleas. Axel’s claim isn’t just a theoretical dream – laminar flow over both wings with equal vertical and horisontal separation has been verified experimentally with wool tuft tests.

So what are the lessons to be learned from this?

- We need to have equal horisontal and vertical wing separation if we want laminar flow over both wings. The “standard” wing separation on ALL fleas is impossible to produce laminar flow.

- As a consequence of the laminar flow, the NACA23112 airfoil as used on most modern Poux no longer needs to stall at 12 degrees, but incidence of up to 20 degrees can be achieved, giving a landing lift coefficient of close to TWO…

- And with this increased lift comes far slower stall speeds.

Axel concludes:

“In the final analysis, I found that starting at 90cm/90cm

[ED: i.e. vertical and horisontal wing separation] with any

of the most used aerofoils on Pou’s that they

remained in laminar flow all the way down to about

20cm/20cm. Of course below 50 or 60cm it isn’t of

practical use”

The TCF has vertical and horisontal wing separation of 70cm. Right in the sweet spot. Achieving this on such a small plane was no easy feat, and required the rear wing to be mounted inside the tail section, rather than on top of the turtledeck as is the case with all Flying Fleas of which I am aware, including the HM293 pictured below..

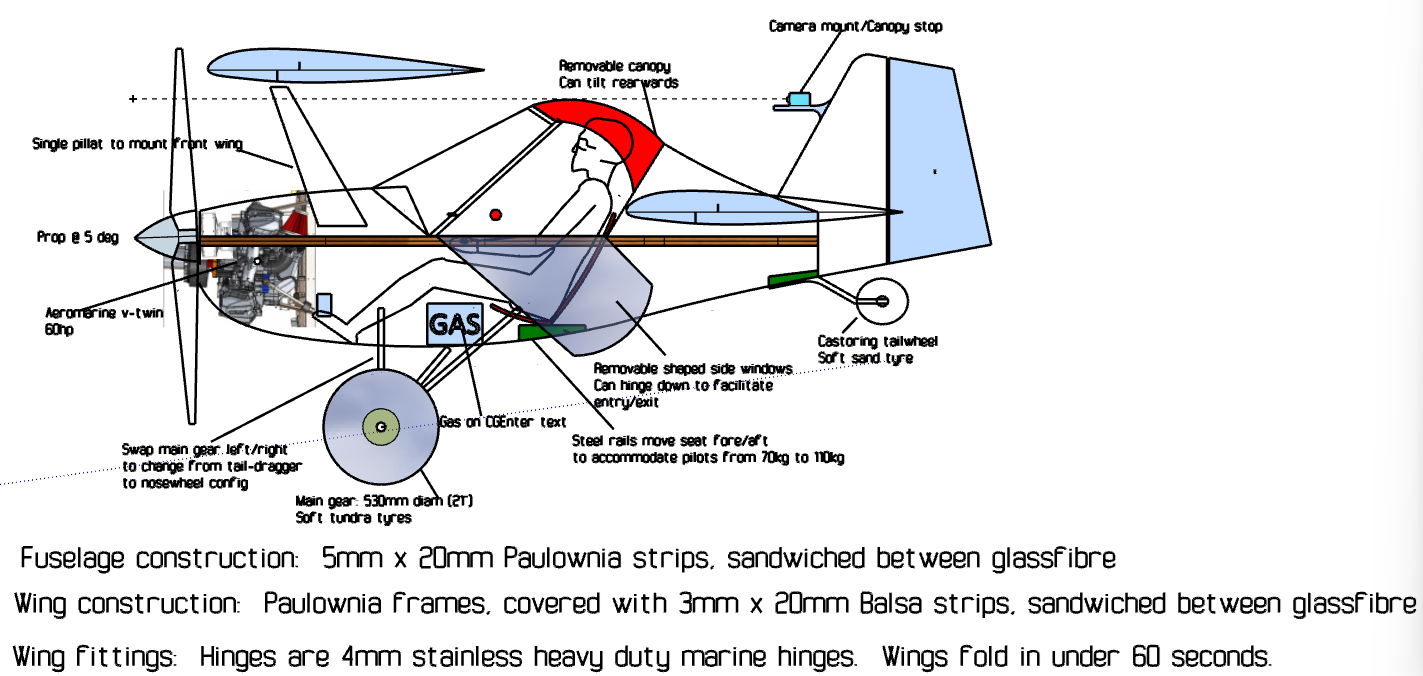

One of the great things about designing a plane from scratch is that one doesn’t have to (for example) choose between it being a tail dragger or a nosewheel configuration. You can quite happily have both for the price of one.

One of the great things about designing a plane from scratch is that one doesn’t have to (for example) choose between it being a tail dragger or a nosewheel configuration. You can quite happily have both for the price of one. Hi, and welcome back. While I wait for parts to arrive for the CNC, I’ve been hard at work checking and double-checking the Tiny Cedar Flea design. Here is where the design currently stands:

Hi, and welcome back. While I wait for parts to arrive for the CNC, I’ve been hard at work checking and double-checking the Tiny Cedar Flea design. Here is where the design currently stands:

This is the Veritas mini edge plane. It is a thing of miniature beauty, with a blade which is only 6mm wide. Fortunately, the strips on the Tiny Cedar Flea are 5mm thick, so yhis is perfect. Nich Schade of Guillemot Kayaks has created a tool which uses this little plane to perfectly plane the edges of each strip so that they butt up against each other perfectly.

This is the Veritas mini edge plane. It is a thing of miniature beauty, with a blade which is only 6mm wide. Fortunately, the strips on the Tiny Cedar Flea are 5mm thick, so yhis is perfect. Nich Schade of Guillemot Kayaks has created a tool which uses this little plane to perfectly plane the edges of each strip so that they butt up against each other perfectly.

The circled bit is the fixture in question. It protrudes from the fin with a rubber tip to stop the canopy from tilting back too far. But it ALSO acts as a very convenient mount for a Go Pro (or similar) giving a near-pilot view of the flight (see the dotted line of sight). And finally, it can house an external antenna for your radio or nav.

The circled bit is the fixture in question. It protrudes from the fin with a rubber tip to stop the canopy from tilting back too far. But it ALSO acts as a very convenient mount for a Go Pro (or similar) giving a near-pilot view of the flight (see the dotted line of sight). And finally, it can house an external antenna for your radio or nav.